Your Essential Guide to Coated Fabrics

We have put together a comprehensive guide to assist you in understanding the performance and sustainability characteristics of a diverse range of PVC-free alternative upholstery options.

By Mary Holt

More and more institutions are demanding accountability in materials specification, which includes sustainable, high-performing upholstery options for commercial interiors and exteriors. Designers increasingly seek to have a clear understanding of available alternatives to PVC-based textiles and their unique features. From performance attributes such as durability, stain resistance, and cleanability to sustainability programs including Healthier Hospital Compliant and Mindful Materials, there are a wide variety of PVC-free upholstery options to choose from. So many in fact, that it can be overwhelming knowing where to start.

Whether you're involved in designing spaces for healthcare, workplace, hospitality, or other projects, this guide was put together to equip you with the knowledge needed to make informed decisions.

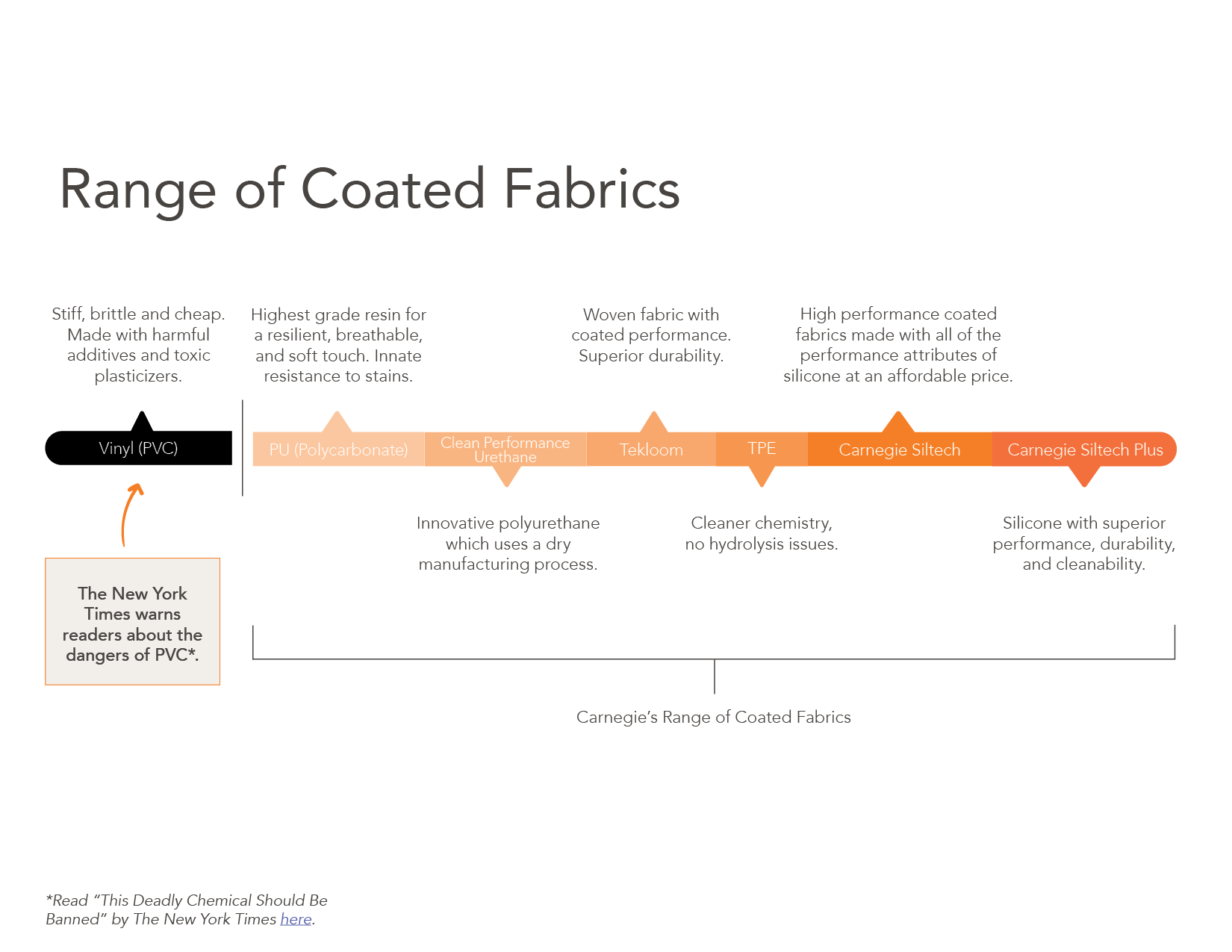

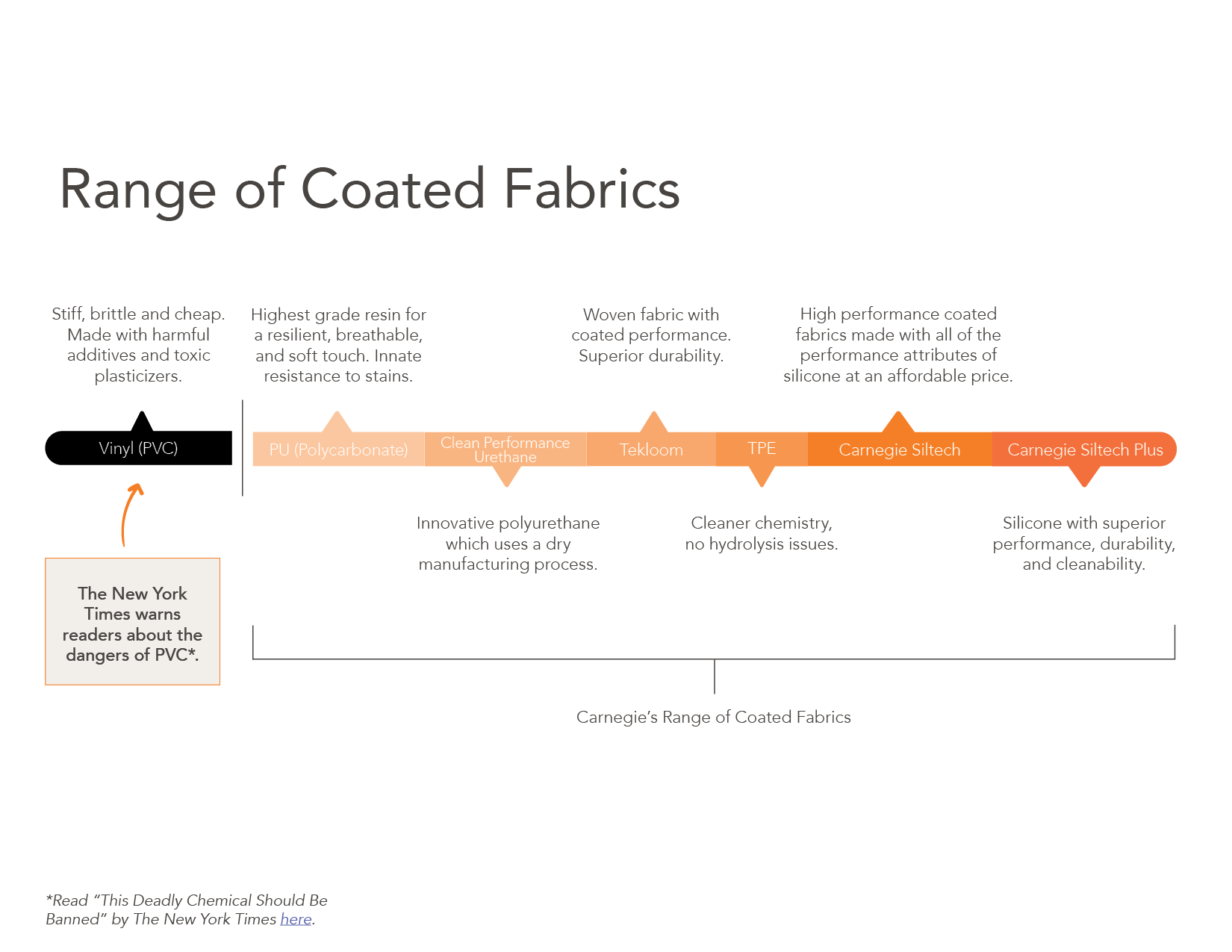

Carnegie's Range of Coated Fabrics

Read “This Deadly Chemical Should Be Banned” by The New York Times here.

Coated fabrics are made with one or more layers of a film-forming polymer, chemically bonded together to create an impermeable and very cleanable surface. With so many different types, how do you know which ones are safe, sustainable, and right for your project?

Polycarbonate Polyurethanes

This is the highest performing polyurethane resin on the market. It has a higher resistance to humidity and greater hydrolysis (a breakdown or delamination of the polyurethane film layer from the backing substrate in the form of cracking and peeling due to extreme heat and humidity) rating than other lesser polyurethanes. However, not all polyurethanes are created equal. There are three types of resins used to create polyurethanes with polycarbonate being the best:

1. Polycarbonate

· High Abrasion

· High resistance to humidity

· Hydrolysis 7-15 weeks

· Ideal for high traffic commercial applications

2. Polyether

· Average abrasion

· Average resistance to humidity

· Hydrolysis 3-5 weeks

3. Polyester

· Low abrasion

· Low resistance to humidity

· Hydrolysis 1-2 weeks

You can rest easy knowing that all of Carnegie’s polyurethanes are made from the highest quality resin, which translates to performance and longevity in the field without harmful chemistry.

Performance benefits:

· High resistance to humidity

· Hydrolysis 7-15 weeks

· Minimum 250,000 double rubs Wyzenbeek

· Inherently antimicrobial

· Bleach cleanable

· Approved for hospital grade disinfectants

· 5 year warranty

Clean Performance Urethane (CPU)

Carnegie’s Clean Performance Urethane (CPU) coated fabrics utilize a new process to make the middle foam layer without requiring any added DMF solvents. Conventionally, the middle layer of a coated fabric was made with a ‘wet method’, a process known for having quality issues and added chemicals such as DMF type solvents for processing. CPUs do not undergo this traditional ‘wet method’ and uses zero water, resulting in an environmental manufacturing process that not only saves water but also does not contaminate any water resource.

Performance benefits:

· Minimum 100,000 double rubs Wyzenbeek

· Minimum 10 week hydrolysis

· Extremely low VOCs

· Inherently antimicrobial

· Bleach cleanable

· Approved for hospital grade disinfectants

· Inherently flame resistant

· Minimum 5 year warranty

Tekloom

Tekloom is a brand name for a proprietary process where a woven textile is chemically bonded with the durable components of a coated top layer to create a fused hybrid textile. Tekloom allows you to achieve the look and feel of a woven textile with the performance, durability, and cleanability of a coated fabric. It’s perfect for environments that call for a softer, more sophisticated texture and feel, but need to be easy to clean and maintain on a commercial level.

Performance benefits:

· Ink & stain resistant

· 1 million double rubs Wyzenbeek

· Approved for IMO use

· 15 week hydrolysis

· Extremely low VOCs

· Inherently antimicrobial

· Bleach cleanable

· Approved for hospital grade disinfectants

· Inherently flame resistant

· 5 year warranty

Thermoplastic Elastomer (TPE)

A compound made from rubber and thermoplastic materials that consists of both thermoplastic (heat-sensitive) and elastomeric (rubber-like) properties. TPE coated fabrics are engineered to be impervious to hydrolysis issues due to their ability to stretch and return to their original shape, creating a longer life and better physical range than other materials. These fabrics are great in the hospitality, retail, and dining sectors because they can fit a variety of different furniture shapes.

Performance benefits:

· Minimum 200,000 double rubs Wyzenbeek

· Healthier Hospitals Initiative (HHI) / Kaiser approved

· Red List Free

· 15+ week hydrolysis

· No hydrolysis or puddling issues

· Extremely low VOCs

· Inherently antimicrobial

· Bleach cleanable

· Approved for hospital grade disinfectants

· Inherently flame resistant

Carnegie Siltech

Carnegie Siltech is a line of high-performance, sustainable coated upholstery fabrics designed as alternatives to PVC-based textiles with all of the performance of silicone. These budget friendly fabrics offer excellent durability and aesthetics, making it suitable for high-traffic spaces and a variety of design needs.

Performance benefits:

· Minimum 100,000 double rubs Wyzenbeek

· 10 week hydrolysis

· Extremely low VOCs

· Inherently antimicrobial

· Bleach cleanable

· Approved for hospital grade disinfectants

· Inherently flame resistant

· 5 year warranty

Carnegie Siltech Plus

Carnegie Siltech Plus is a premium line of high-performance silicone-coated upholstery fabrics. These fabrics are designed for superior durability and performance, delivering unmatched scratch and tear resistance, along with incredible stain resistance and ease of cleaning. Ideal for high-traffic spaces, Carnegie Siltech Plus provides a robust and sustainable alternative to PVC-based textiles without sacrificing aesthetics or functionality.

Performance benefits:

· Unmatched scratch and tear resistance

· Minimum 200,000 double rubs Wyzenbeek

· 15 week hydrolysis

· Extremely low VOCs

· Inherently antimicrobial

· Bleach cleanable

· Approved for hospital grade disinfectants

· Inherently flame resistant

· 10 year warranty

Coated Fabrics Matrix

Siltech Plus

Siltech

Vinyl Alternative Upholstery

Hydrolysis

Abrasion

Warranty

Price Range

Our Forever Promise

Staying true to our forever promise of being 100% PVC-free, PFAS-free, and finish-free, all of our coated fabrics are always free of harsh chemicals including antimicrobials, antimony, bisphenol A (BPA), chlorine, DMF, formaldehyde, halogenated fire retardants, heavy metals, ozone-depleting chemicals, PFAS, phthalates, plasticizers, solvents, and stain resistant finishes—giving you peace of mind and a wide design palette when specifying our fabrics for all your high-traffic commercial environments.

For additional resources on coated fabrics, visit our curated hub of information here.

About the Author

Mary Holt is the Chief Design Strategist at Carnegie. With over 30 years of experience, Mary is passionate about solution-driven design and ethical and sustainable product development. She was previously featured in Interior Design, Officeinsight, BoF, and Metropolis Magazine among other places.